Plastics are ubiquitous in modern life; unfortunately, once they lose function, they pollute the environment. Now, researchers at Osaka University have developed polymer materials that combine self-healing with strength and recyclability that could extend the functional lifetimes of manufactured plastics, thus minimizing the surging problem of discarded remnants.

Polymers are versatile substances, composed of many repeating molecular subunits, with essential and diverse functions in biological processes and industry. Sadly, their durability is double-edged: waste plastics generate litter and can contaminate our environment for centuries. About 50 kg of plastics is produced annually for every human; this doubles every decade. By the year 2050, there may be more plastics in our oceans than fish. As plastics are indispensable, extending their functional life by enhancing durability, self-healing and recyclability can help reduce waste.

Host–guest interactions, a fascinating branch of supramolecular chemistry, describes molecular complexes held in unique structural relationships by non-covalent bonding. These physical linkages allow molecular recognition and are ideal for preparing materials with rapidly reversible properties.

“We prepared supramolecular materials by mixing host and guest polymers of acetylated β-cyclodextrin and adamantane,” explains Junsu Park, lead author. “We compared three mixing methods: conventional casting, planetary kneading and ball-milling. Ball-milling employs zirconia balls in a zirconia grinding jar on a sun-wheel revolving eccentrically in reverse. The additional rotational forces on the grinding surfaces and the interplay between impact and friction cause nanoscale mixing.”

The researchers analyzed the polymers by wounding, re-joining, as coating of a glass substrate and after repeated ball-milling. Using dynamic mechanical analysis, thermal property measurements, small angle X-ray scattering measurements, and confocal laser scanning microscopy, etc they assessed scratch resistance, deformability and tensile strength.

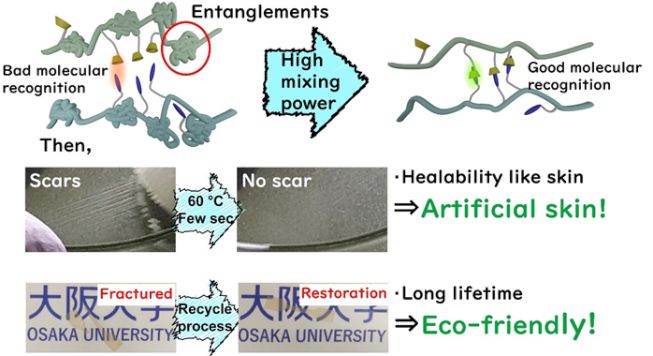

The results were remarkable. Planetary mixing efficiently produced tough, self-healable, and recyclable supramolecular materials. Surface scratches disappeared in seconds and fractured fragments united in minutes. Moreover, mechanical properties were preserved even after repeated milling. “Ball-milling disentangles the polymer chains in the materials and increases their mobility while facilitating their re-formation,” Park explains. “This maintains the number of host–guest interactions, ensuring both self-healing and toughness.”

Senior author Yoshinori Takashima describes the potential of these discoveries: “We can develop tough materials capable of self-repair that retain these properties even when recycled. Prolonging their functional lifespan is key to saving the environment as they are being increasingly deployed in manufacture. Additionally, their unique biomimetic properties open up avenues of application in fields such as artificial skin for prostheses, robots and even vehicles.”

Fig. Schematic of internal structures of the materials and their functions.

Generally, entanglements of polymer chains retard effective molecular recognition. Planetary mixing detangles the chain entanglements to allow effective molecular recognition. The materials then exhibit extremely rapid self-healing and recyclable properties.

The article, “Extremely rapid self-healable and recyclable supramolecular materials through planetary ball milling and host–guest Interactions,” was published in Advanced Materials at https://onlinelibrary.wiley.com/doi/10.1002/adma.202002008.

Related links

Takashima Laboratory, Institute for Advanced Co-Creation Studies, Osaka University

EurekAlert!

AlphaGalileo

ResOU(Research at Osaka University)website